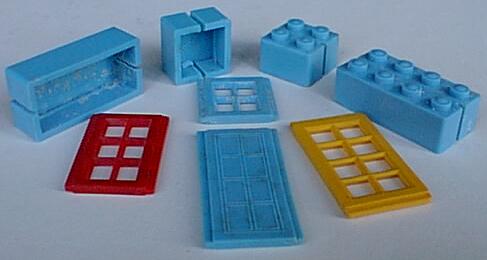

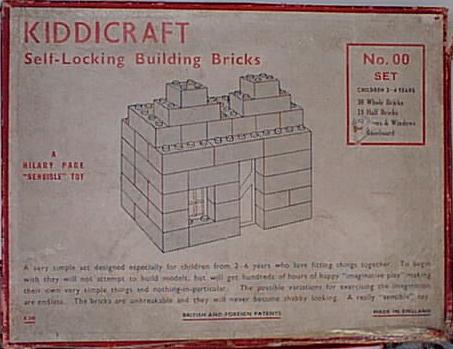

After Alexander Parkes unveiled the first plastic, the cellulose-based Parkesine, in 1862 there was considerable interest and research into the new material: celluloid and cellulose acetate were in use by the turn of the century, bakelite by 1910, and viscose (or rayon) by 1939. But the dramatic pace of research, development and manufacturing as part of the war effort is really when the industry took off. After the war the market was flooded with low-cost plastic consumer goods, and especially for our purposes, with new plastic toys. Apparently Ole had been paying attention and he began to study the idea of using plastic for his toys. Against the advice of those around him, he bought a plastic injection molding machine from Windsor, Ltd. in England in 1947. The new machine cost 30,000 DKK, more than twice the previous years’ profits. He initially wanted to buy three of the machines but, at least temporarily, the rest of the family managed to hold him back. Plastics were gaining widespread acceptance and use in Europe but there was still considerable risk with Ole’s new idea. It was the first injection molding machine in Denmark. The company wasn’t even sure it could source replacement parts, molds, or the necessary raw materials. For the next two years the company worked on designing new toys and trying to obtain a source for cellulose acetate. They finally found a supplier in England. Along with the new machine Ole received several sample parts showing its capabilities. Among these were samples of a toy brick made by Injection Moulders, Ltd, of London. It was Hilary Fisher Page’s Kiddicraft brick. The new material meant new designs, and the first plastic toys, made of cellulose acetate, were much different than the existing wood toys. Early examples, first marketed in 1949, include a fish-shaped baby rattle, a bear in an airplane and a new toy block. Lego had long made traditional cube-shaped wooden blocks (“Lego Klodser”) but Ole wanted to try something else with plastic. He turned to the sample Kiddicraft block and tried to copy it. The result was the Automatic Binding Brick, and the beginning of the Lego empire. The original elements were 2 × 2 and 2 × 4 bricks with 2 side slits and 2 × 2, 2 × 3 and 2 × 4 panel windows and 2 × 4 panel doors. The earliest elements had no identifying marks anywhere on the brick. Later in 1949 new molds were introduced that had a block letter “LEGO” molded on the underside. The first Automatic Binding Brick sets were known as Gaveæske (Gift Sets). (4) (4) Note that Automatic Binding Bricks was the Danish name. After the War it was a common practice among Danish companies to use English names for their products. In 1949 at least 4 different sets were released: 700/1, 700/2, 700/3 and 700/4 (listed in descending size). In 1950 the 700/3A (between 3 and 4 in size), 700/5 and 700/6 sets were released. The gift sets were simply boxes of elements hand packaged in a zig-zag pattern in a shallow box. This packaging formed the basis of the basic set and has been the primary way Lego has been sold ever since. The 700/x set numbers and generic packaging would last until the mid 1960’s. The original Automatic Binding Brick sets were only available in Denmark and even then they were not widely distributed. Retailers were not very interested in the sets and would only accept them if they could be returned. They did not sell particularly well and many were returned unsold to Lego. |