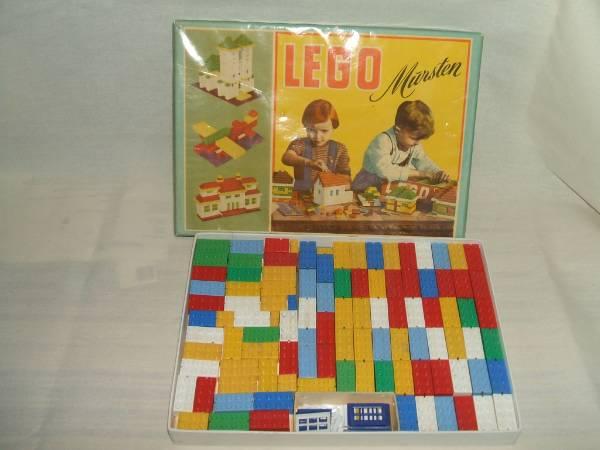

LEGO Mursten.

After the Danish trade magazine Legetøjs-Tidende visited the Billund factory in 1950 they wrote that “Plastic toys will never take the place of good, solid wood toys.” But, in retrospect, it appears that they may have been wrong: plastic consumer goods, including toys, were starting to gain public acceptance in Europe. Lego saw a dramatic spike in plastic toys sales in 1952 and by 1953 they accounted for nearly half of the company’s revenue.

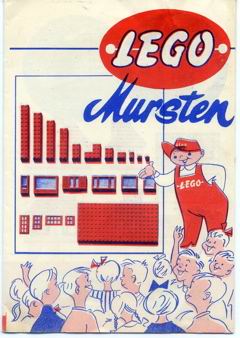

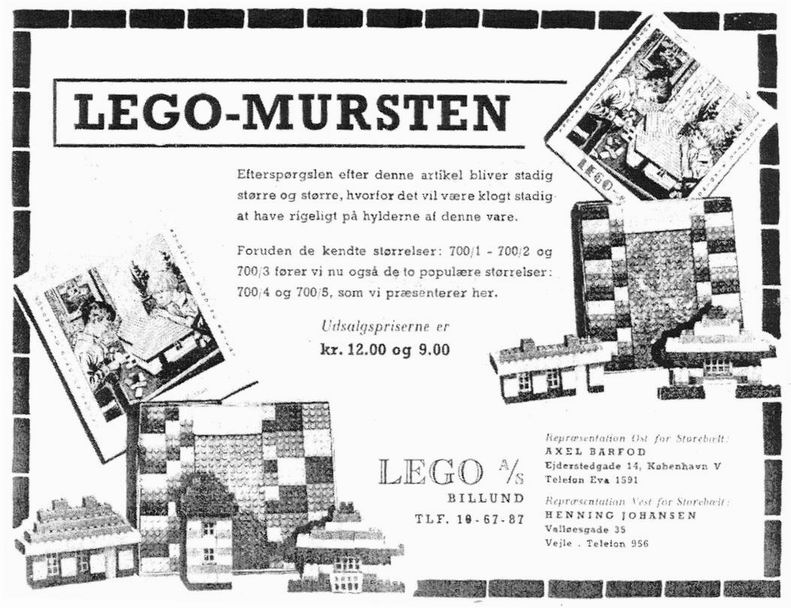

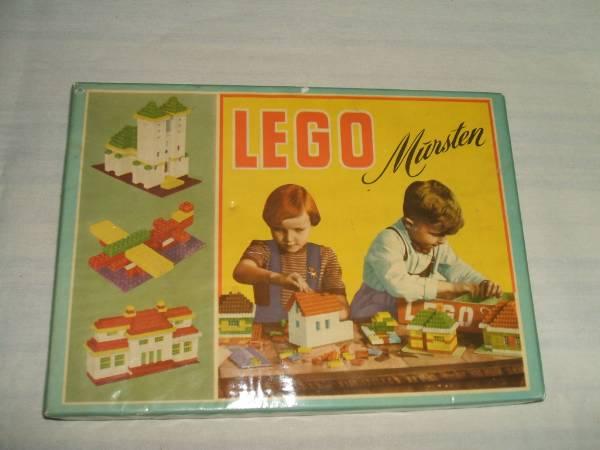

Despite their success with plastic toys, the Automatic Binding bricks were still not selling very well. At most they accounted for about 5–7% of total sales. In 1952 Godtfred decided that they needed a more descriptive name and he added the phrase “Lego Mursten” (Lego bricks) to the boxes and in 1953 the sets were renamed simply Lego Mursten.

The first export.

In 1953 Godftred found his first foreign partner, Svein Strømberg, Akersgaten 39, Oslo, Norway. Svein Strømberg & Co. A/S, was founded in 1941, began plastic production in 1946, and by the early 1950’s was a significant manufacturer of plastic household goods. Due to Norwegian import restrictions at the time Lego could not directly export the finished toys so they began a licensing arrangement. Strømberg set up a manufacturing and sales division, Norske Lego A/S, and licensed the molds and technical knowledge from Billund. Lego received royalties on sales.

Norske Lego produced several Lego designs, including the Ferguson Traktor and most importantly the Lego Mursten. They also licensed and manufactured many different toys from other companies, including the plastic Lego Byggepinner and the die-cast Tekno vehicles, which were marketed under the names Mecline, Mini-Cars, or Nikrom.

The license lasted until 1962 when manufacturing reverted back to Billund. Lego set up its own Norwegian sales division; also under the name Norske Lego A/S.

The Iceland Licence.

In what would be their most unusual license arrangement, Lego licensed the molds for Lego Mursten to SÍBS in Iceland in 1956. (2) (2) SÍBS is the acronym for Sambands íslenskra berkla- og brjóstholssjúklinga (Icelandic Association of Tuberculosis and Thoracic Patients), but you probably knew this already. Reykjalundur was sold to private investors in 2004 and is now Reykjalundur Plastiðnaður (Reykjalundur Plastics Industries, Ltd). SÍBS was established in 1949 in Reykjavik as a rehabilitation center for tuberculosis patients and included an occupational therapy center, Reykjalundur. Arni Einarsson, the director of SÍBS, was looking for relatively simple plastic products for the patients to manufacture. Through a third party, Elmo Nielsen of the Copenhagen wholesale company Elmodan, he obtained Lego Mursten molds in 1955.

From 1955–1960 the Icelandic sets were not sold as Lego, but under the name SÍBS kubbar (SÍBS building blocks). Around 1960 SÍBS looked into printing their own Lego boxes and found that it was cheaper to buy the packaging directly from Billund. From this point on the sets were sold under the Lego name.

Later, in 1974, SÍBS began Duplo production and they continued to mold, package and distribute Lego until 1977, By this time the system became simply to large and complex. Lego in Billund took over manufacturing and packaging but, due to the small size of the market and the unusual nature of the licensee, Reykjalundur continued the distribution of Lego in Iceland, a practice that continues to the present day.

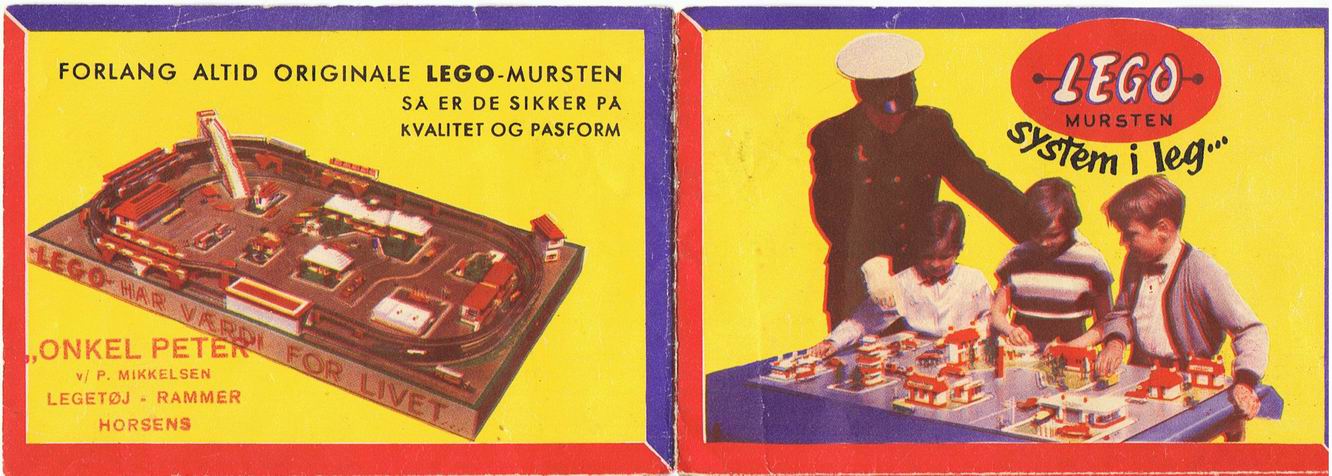

Although theses were baby steps, taken in small markets close to home, they were the beginning of Lego’s world domination. Godtfred largely relied on licensing for these early exports but soon realized that his only chance at foreign success was to have his own sales companies. As he explained in 1967: “We would have disappeared in the multitude of competitors if we had placed ourselves in the hands of wholesalers.”

Lego Mursten

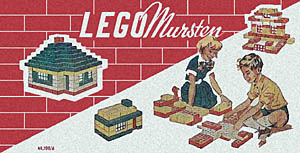

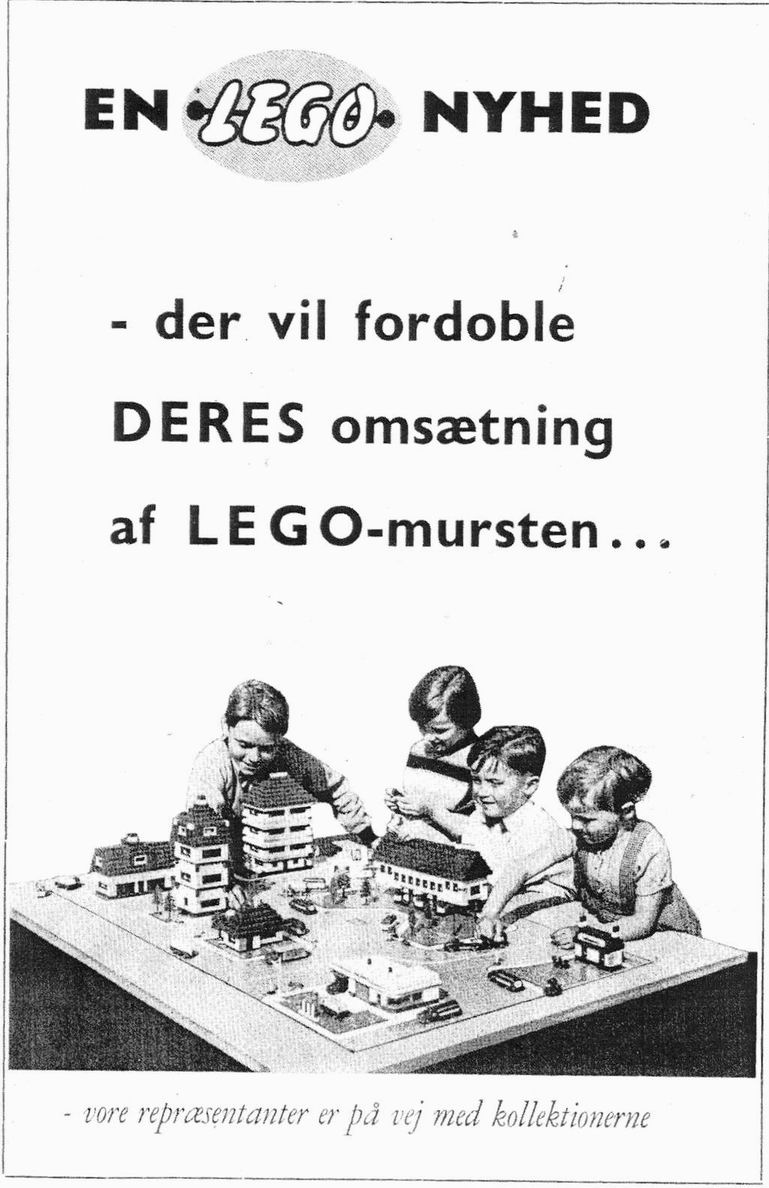

Despite poor sales, Godtfred and Ole apparently had faith in the Lego Mursten and continued to expand it. But with no specific concept or plan in mind the result was a rather confusing marketing approach. From 1951–1955 Lego Mursten was sold as Gift Sets, Supplementary sets and even as single pieces. And these were packaged in no less than three completely different box styles, each overlapping the other.

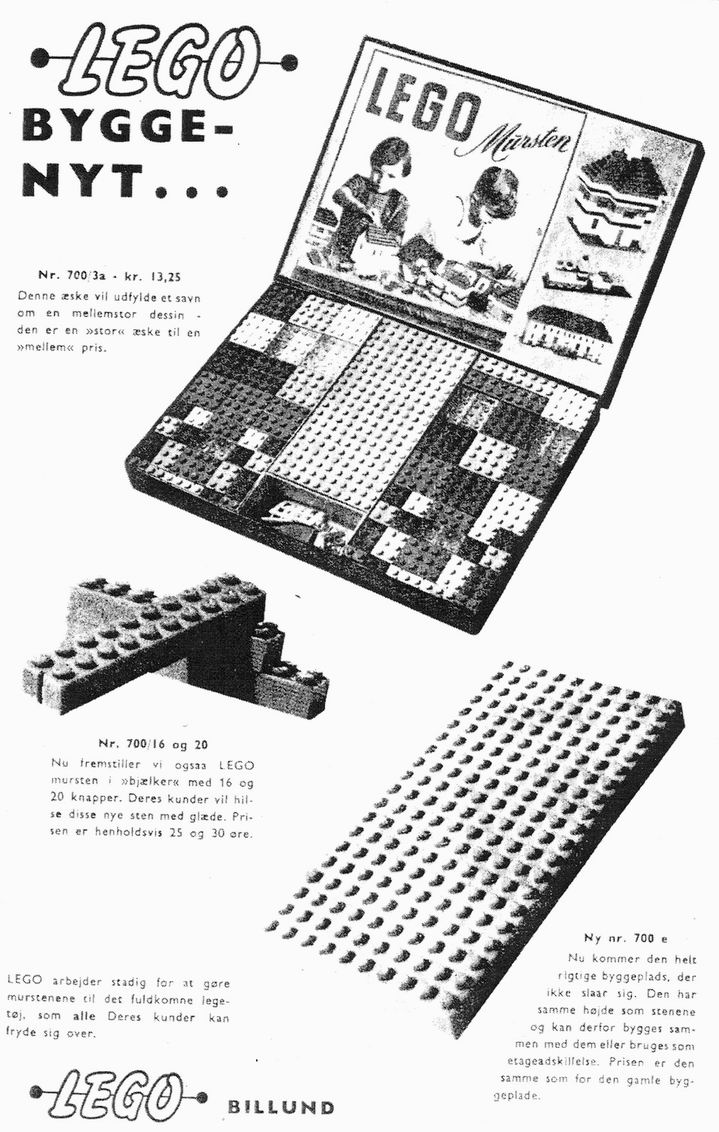

- 1951: 10 × 20 thin baseplate

- 1953: 1 × 2 and 2 × 3 bricks, 10 × 20 baseplate (700/E)

- 1954: 1 × 1 round and square bricks

- 1954: 2 × 8, 2 × 10, 2 × 12, 2 × 14 beams

- 1954: 4 × 4 corner brick

- 1955: plates (1/3 height bricks)

- 1953: 1 × 2 and 2 × 3 bricks, 10 × 20 baseplate (700/E)

They also introduced a new system of five windows and a door in 1954. The new windows had “wings” on the bottom that fit around the studs of the bricks and did not need the slots. But, to add to the confusion, this new system didn’t replace the old one, both types of windows were sold simultaneously until 1956. By the end of 1954 there were 22 different elements available.

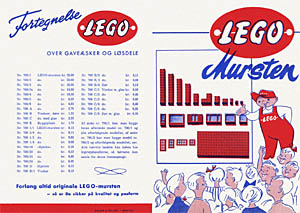

During this time Lego also began individual parts sales, a practice that began with the Ferguson Tracktor in 1951. Lego would supply dealers with wooden parts boxes and refill packs. It was possible, for example, to buy a single 1 × 2 brick (700 1/4: 0.06 DKK) or single 2 × 4 brick (700 1/1: 0.13 DKK). The 1954 price list had 20 different individual elements. These individual part sales would continue, at least in some markets, into the late 1950’s.

Although Lego had clearly expanded the Lego Mursten range, and, one could argue, even began to develop a cohesive system with the new windows and doors it would take another year for all of Godtfred’s ideas to fall into place.

See this catalogue in large format, click here!